MK KOLEKT multi

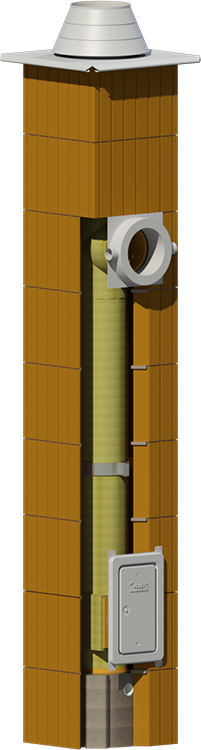

A modular chimney system MK KOLEKT multi is used not only with modern solid and liquid fuel boilers (temperature below 200oC), but also with modern heating systems. The three-layered chimney system is fully insulated with mineral wool and corresponds the highest requirements for chimney system elements. Ceramic elements are centered with centering rings. The air gap between ceramic flue liner and block wall is used for air supply to the heating device. Ceramic elements produced by the German manufacturer, in Germany, corresponds W3G requirements. Ceramic chimney system parts are resistant to soot ignition even when working at wet conditions, also resistant to low and high temperatures (60oC - 600oC). A ceramic liner has smooth surface and is highly resistant to condensate effect (resistant to aggressive corrosive factors). In the three-layered chimney system MK KOLEKT multi is used special shaped insulation. It is possible to order chimney liners with a mineral wool on it. Installation of the chimney system MK KOLEKT multi is simple, easy and fast process. Quality of MK KOLEKT multi system elements is also approved by issued CE certificate of conformity.

The chimney for a passive house

The chimney design used in a passive house differs from the standard chimney design. The standard ceramic chimney does not meet the requirements as for ventilation of the ceramic elements is used air from the room. The new generation systems, suitable for a passive house differs from the previous ones in a tightness - there is no need to ventilate ceramic elements and an air gap between centered ceramic elements and block walls is used to supply heating devices with an air. The ceramic element wall is thinner then standard chimney system walls. Chimney systems are resistant to the moisture, there is no a dew point. It determines the advantage of ceramic chimney systems against steel systems. Both types of chimney systems are suitable for an A++ class buildings, but it is important to pay attention to the tightness and the formation of a "cold bridge". When installing stainless steel chimney system to the passive house it must be taken to the attention, that it might have a problem of the "cold bridge". Standard heating devices, which takes air from the room, can't be used in a A class buildings. The buildings in this class require certified facilities, which have an external air connection for combustion and have a secondary combustion system.

Characteristics of a three-layered chimney system

MK KOLEKT multi |

|

Fast, good traction; Resistant to acids; Resistant to high temperature exposure. |

| For heating devices, which uses different type of fuel (firewood, coal, gas, pellets and etc.). |

| Suitable for operation with a closed combustion chamber boilers and condensing boilers, suitable for use as a concentrated condensing chimney system, where a separate air supply to the heating system is required. |

| Ceramic flue liners resistant to soot ignition and meets W3G requirements. |

| Ceramic insert designed to work at high and at low temperatures (from 60 to 600 oC). |

| Ceramic flue liner has a smooth surface. It is highly resistant to condensate effect. |

| Ceramic liners are manufactured in various diameters (mm): Ø120;Ø140; Ø160; Ø180; Ø200; Ø250; Ø300. |

| Ceramic insert with a thin wall, with a same durability as a thick-wall ceramic insert. |

| Insulated ceramic elements are centered with a centering ring. |

| Air gap between centered ceramic element and wall of block is used for boiler air supply. |

| Because of the long inserts there are small number of joints. |

| Fire resistance - 90 min. |

| Fast and easy installation. |

| Product is certified. |

MK KOLEKT multi parts

The three-layered chimney system MK KOLEKT multi consists of: expanded clay or ceramic chimney blocks, mineral wool, ceramic elements and other accessories. Standard chimney system set: chimney blocks, mineral wool, centering rings, a ceramic condensation container, flue liners, a cleanout tee, a connection tee, glues for ceramic elements, a cleanout doors. We are also offering to buy those accessories: a chimney ending pack, a stainless steel connection adapter, a masonry mixture.

- Accessories

Accessories which goes with a standart MK KOLEKT multi chimney system:

- Cleanout doors;

- Centering ring.

Additional accessories:

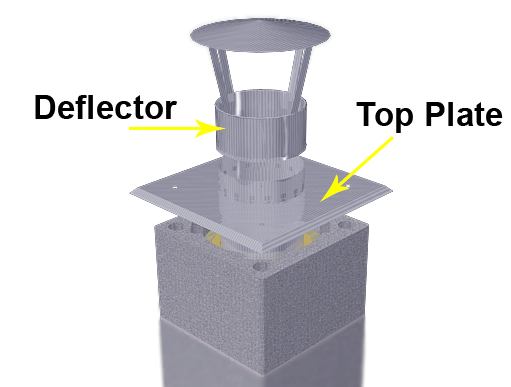

- Chimney top pack, which consists of stainless steel chimney top plate and roof. It's possible to choice: stainless steel chimney top plate with a deflector or a roofing. For a passive house we are offering chimney top with an air intake;

- Stainless steel connection adapter. For a passive house we are offering an adapter with an air supply;

- Masonry mixture - MK KOLEKT Mix.

| Chimney ending with a roof | Chimney ending with a deflector |

|

|

| Chimney top with an air intake | |

|

|

| Cleanout Doors |

|

| Centering ring |

|

| Conn. adapter 1* |

|

| Conn. adapter 2* |

|

| Patterns** |

|

| Masonry mixture* |

|

**Accossories which goes with a chimney ending pack, when buying the MK KOLEKT chimney system

- Ceramic elements

Ceramic elements which goes with a standart MK KOLEKT chimney system:

- Condensation container;

- Cleanout tee;

- 90o connection tee;

- Flue liners.

| Connection tee 90o | |||||

| Code | Height (cm) | Weight (kg) | Pallet (unit) | ||

|

RRO300M | 100 | 32 | 6 | |

| RRO250M | 100 | 22,1 | 8 | ||

| RRO200M | 100 | 22 | 12 | ||

| RRO180M | 100 | 22 | 12 | ||

| RRO160M | 100 | 15,6 | 15 | ||

| RRO140M | 100 | 15,6 | 20 | ||

| RRO120M | 100 | 10,2 | 20 | ||

| Cleanout | |||||

| Code | Height (cm) | Weight (kg) | Pallet (unit) | ||

|

PTO300M | 66,5 | 22,1 | 6 | |

| PTO250M | 66,5 | 15,1 | 8 | ||

| PTO200M | 66,5 | 10,2 | 12 | ||

| PTO180M | 66,5 | 9,9 | 15 | ||

| PTO160M | 66,5 | 9,3 | 15 | ||

| PTO140M | 66,5 | 8,4 | 24 | ||

| PTO120M | 66,5 | 7 | 28 | ||

| Ceramic flue liner | |||||

| Code | Height (cm) | Weight (kg) | Pallet (unit) | ||

|

KLR300M | 100 | 29,95 | 6 | |

| KLR250M | 100 | 20,45 | 8 | ||

| KLR200M | 100 | 15,2 | 17 | ||

| KLR180M | 100 | 14,05 | 20 | ||

| KLR160M | 100 | 12,4 | 20 | ||

| KLR140M | 100 | 10,6 | 24 | ||

| KLR120M | 100 | 9,85 | 28 | ||

| Condensation container | |||||

| Code | Height (cm) | Weight (kg) | Pallet (unit) | ||

|

SO250M | 50 | 12 | 8 | |

| SO200M | 50 | 9 | 12 | ||

| SO180M | 50 | 8 | 15 | ||

| SO160m | 50 | 7,5 | 15 | ||

| SO140M | 50 | 7 | 24 | ||

| SO120M | 50 | 6 | 28 | ||

chimney components made in GERMANY goes with

chimney components made in GERMANY goes with

- Other chimney system MK KOLEKT elements

Other elements which goes with standart MK KOLEKT chimney system:

- Glues for ceramic.

| Glues for ceramic |

|

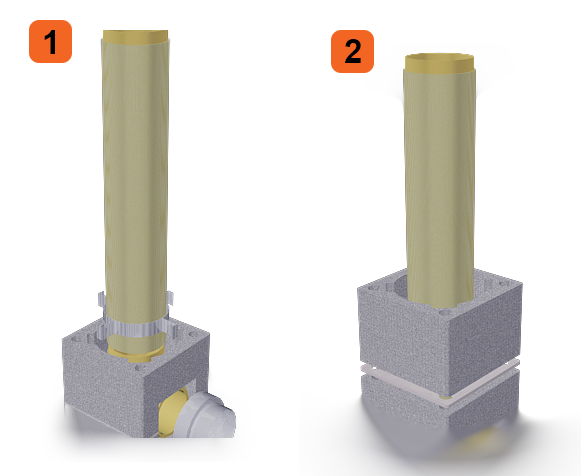

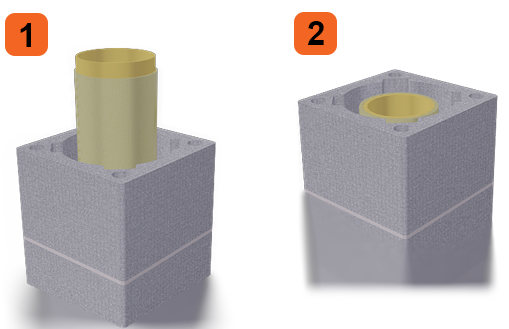

- Chimney system blocks

Expanded clay chimney block to choice:

- Chimney block w/o vent.;

- Chimney block with 2 vent.

Ceramic chimney block to choice:

- Chimney block w/o vent.;

Expanded clay vent. blocks:

- 1-channel ventilation block;

- 2-channels ventilation block;

- 3-channels ventilation block;

- 4-channels ventilation block.

Chimney blocks and ventilation blocks might be built near each other, because they are similar in dimensions.

Chimney blocks

| Chimney block w/o vent. | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

36x36x24 | 12 | 63 |

| Block with 2 vent. | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

56x36x24 | 18 | 42 |

| Chimney block w/o vent. | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

36x36x24 / 42x42x24 | 21 / 27 | -- |

Ventilation blocks

| 1-channel ventilation block | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

25x25x24 | 9 | 90 |

| 2-channels ventilation block | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

36x25x24 | 12,5 | 84 |

| 3-channels ventilation block | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

52x25x24 | 18 | 36 |

| 4-channels ventilation block | |||

| Dimensions (cm) | Weight (kg) | Pallet (unit) | |

|

50x36x24 | 27 | 24 |

MK KOLEKT multi construction advice

| 1 | ADVICE: junction of ceramic flue liner |

| 2 | ADVICE: chimney clearance |

| 3 | ADVICE: ceramic flue tee and cleanout |

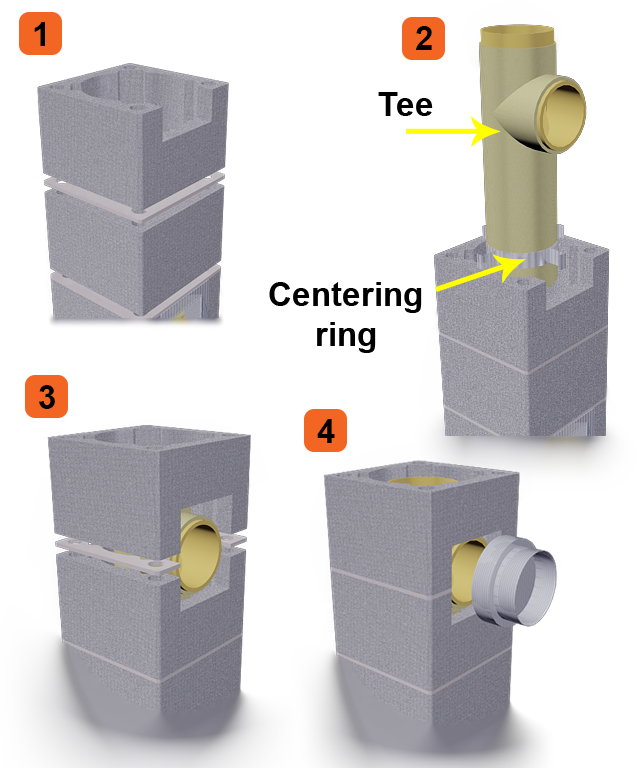

- Before cutting holes in chimney blocks for tee, make sure that there will be left some gap between ceramic elements and walls of hole, so ceramic element has enough space to move when it gets hot.

- We may offer connection adapter which goes on top of connection tee, if You are using connection adapter which goes inside of connection tee, make sure that there will be not used heat-resistant rigid rope to fill air gap between connection tee and adapter walls. Heat-resistant rope must be soft when it's used connection adapter which goes inside connection tee.

MK KOLEKT multi installation guide

Before starting assembling chimney, You must decide: where would be cleanup doors, at which height tee must be installed. If ventilation channel is near chimney, predict ventilation channel height. Free-standing part of the chimney must be statically reinforced. This can be done by fitting the reinforcing bars. Reinforcing bars must be centered inside holes at the corners of blocks, mixed grouting mortar poured into the reinforcing channels.

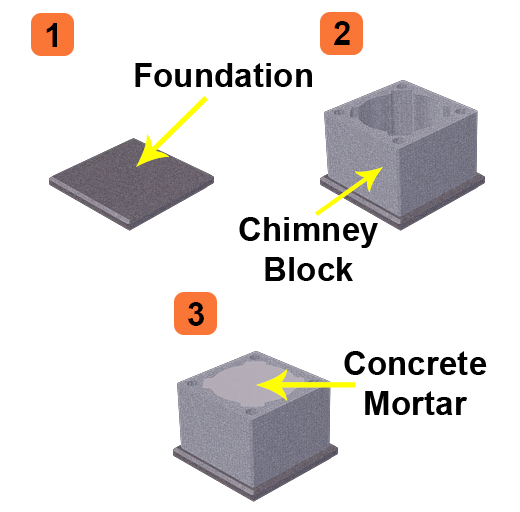

- Build the chimney on a pre-prepared concrete foundation.

- Connect blocks using mortar.

- Place mortar on the walls of blocks (ventilation channels at the corners of blocks and mineral wool must not contact with mortar).

- Ceramic elements are connected with special acid-resistant glue. Before lubricating glue You must clean ceramic tube edges. Clean the end of the ceramic flue pipe with a sponge before lubricating glue.

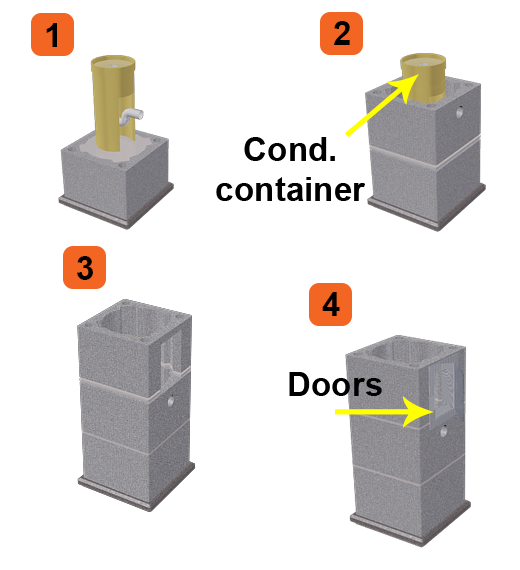

- Connect condensation container to the drain.

If installation is done with a few days break, chimney must be protected from humidity.

| 1 | Sub-floor construction |

- Lay insulation material;

- Construct 20-30 cm sub-floor from concrete or masonry;

- Or first chimney block fill up with a mortar.

| Beginning of construction | 2 |

- Mark out size of the hole onto chimney block wall;

- Cut marked hole with an angle grinder;

- Place the first precut chimney block on the mortar;/li>

- Inside block place a condensation container;

- Mark out size of the hole onto chimney block wall;

- Cut marked hole with an angle grinder;

- Place a precut chimney block on the mortar./li>

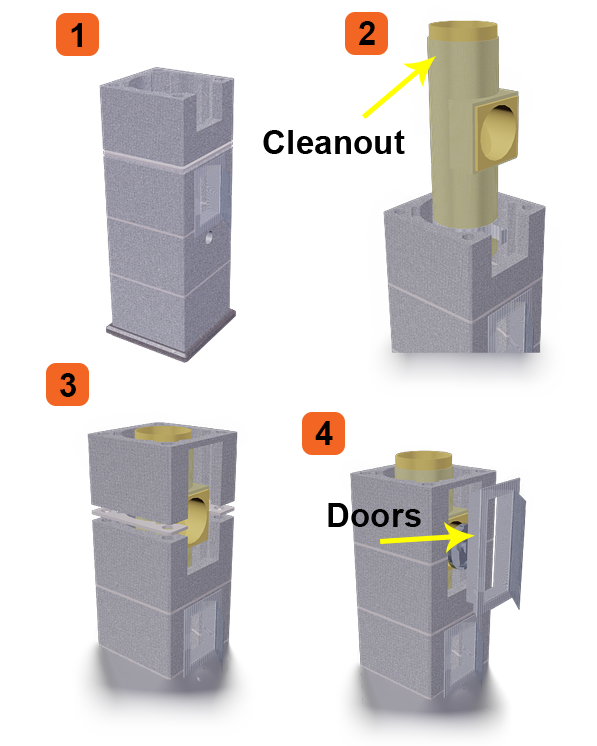

| 3 | Installation of the inspection pipe |

- Mark out size of the inspection pipe hole onto a chimney block wall;

- Cut marked hole with an angle grinder;

- Place block on a bed of mortar;

- Place on a central ring on the inspection pipe;

- Clean edges of the ceramic element and spread a high temperature sealant;

- Insert an inspection pipe;

- Remove excess ceramic sealant with a sponge;

- Mark out size of the required hole onto chimney block wall;

- Cut marked hole with an angle grinder;

- Place block on a bed of mortar.

| Installation of the junction pipe | 4 |

- Place block on a bed of mortar;

- Mark out size of the junction pipe hole onto chimney block wall;

- Cut marked hole with an angle grinder and place a pre-cut block on a bed of mortar;

- Place on a central ring on the junction pipe;

- Clean edges of the ceramic pipe and spread a high temperature sealant on it;

- Insert a junction pipe;

- Remove excess ceramic sealant with a sponge;

- Mark out size of the hole onto chimney block wall;

- Cut marked hole with an angle grinder and place a pre-cut block on a bed of mortar.

| 5 | Standard installation steps |

- Place on a central ring on the flue liner;

- Clean edges of the flue liner and spread a high temperature sealant on it;

- Insert a ceramic pipe;

- Place blocks on a bed of mortar;

- Remove excess ceramic sealant with a sponge.

| Completion of the chimney top | 6 |

- The mineral wool in the last block must be shorter;

- Before inserting the last ceramic pipe, shorten it with an angle grinder;

- Clean edges of the flue liner and spread a high temperature sealant on it;

- Insert a flue liner.

| 7 | Fastening top package |

- Insert fasteners into block to the special fastener holes;

- Fasteners must not be inserted fully, You should leave about 1 cm space;

- Place an upper package on the last block and tighten it with a screw.